With the chip bottlenecks in the Corona crisis, months of waiting for washing machines and cars became just as normal as the futile search for new Playstation consoles. How long will this go on?

Source: dpa

Some experts are cautiously optimistic: Industry analyst Alan Priestley from the IT market researcher Gartner can imagine that overcapacities will occur again in the coming year. At the chip group Intel, however, company boss Pat Gelsinger warns that problems with production capacity and the availability of necessary machines are likely to last at least until 2024.

Expert Priestley is counting on the large-scale expansion of production soon bearing fruit. The industry has been investing in new factories since the first signs of bottlenecks at the beginning of the corona pandemic. “Therefore we will probably have overcapacity in 2023 or 2024,” he predicted. At least until the increasing demand eats them up.

This interplay is in itself typical for the chip industry, stressed Priestley. “As soon as demand and supply are in balance, investments are made in order to have capacities for the next surge in demand.” The current chip crisis was so severe because in some areas not enough was invested in expansion – and at the same time demand increased by leaps and bounds with the increased work and learning in the corona pandemic.

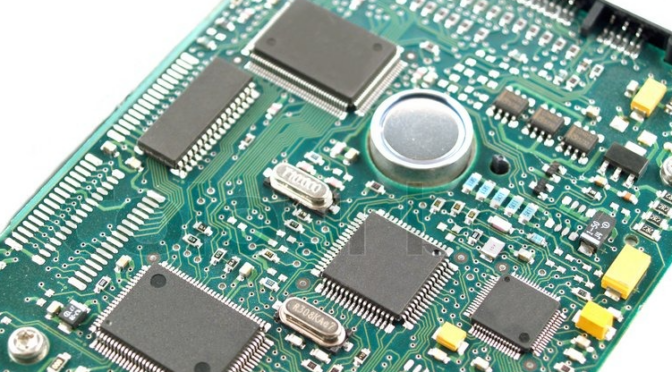

Different chips require different production processes

It makes everything even more complex that there is not just one semiconductor industry. Different chips are required for different tasks – and for these there are different production processes that cannot be arbitrarily interchanged. An important feature is the so-called structure widths – roughly speaking, how finely the circuits are worked. The narrower the structure widths in modern production processes, the more powerful and efficient the processors are.

For something like a transformer or other simple tasks, old production processes are sufficient – which are also less lucrative, so that the capacities for them had leveled off at a low level. And then came the Corona boom. It was often the lack of a few simple components that prevented cars or computers from being completed.

In addition, chip factories not only cost billions and have to be built over years – they are also not necessarily flexible. “If I build a factory for chips with a structure width of seven nanometers, I cannot easily convert them to five nanometers,” says Priestley. And it is not as easy as in other areas to simply let production rest. That’s why companies have to plan their expansion decisions with particular foresight – and new capacities in one area are not necessarily helpful for other parts of the industry.

Machines for chip production are still scarce

Another bottleneck are machines for chip production. With super-narrow structure widths, the only way forward is with UV lithography – and the European manufacturer ASML is practically the only supplier for this. He is accordingly fully booked.

Stories of desperate measures are doing the rounds in the industry. At the presentation of the latest quarterly figures, ASML boss Peter Wennink talked about his conversation with the management of a “very large industrial group”, whose name he kept to himself. “They actually told me that they buy washing machines to rip out semiconductors and put them in industrial modules.” Of course, one could say that this is just an anecdote, admitted Wennink. “But that happens everywhere.”

Another problem for the industry came with the war in Ukraine. The lasers of the lithography machines require neon in addition to other gases. And that’s a common by-product of steelmaking. The huge Azovstal steel works in Mariupol, which has been shelled and bombed by Russian troops in their war of aggression against Ukraine for weeks, was an important supplier of neon. The loss of shipments from Ukraine, while disruptive, will be something the industry will have to digest, Priestley said. “There are also other sources” – including the large steel mills in South Korea.